In the world of manufacturing, the production process for hardware display stands is a crucial aspect of ensuring quality and efficiency. From the initial design phase to the final assembly, every step plays a significant role in creating a product that meets the needs of both manufacturers and consumers.

From Design Blueprint to Customer Customization

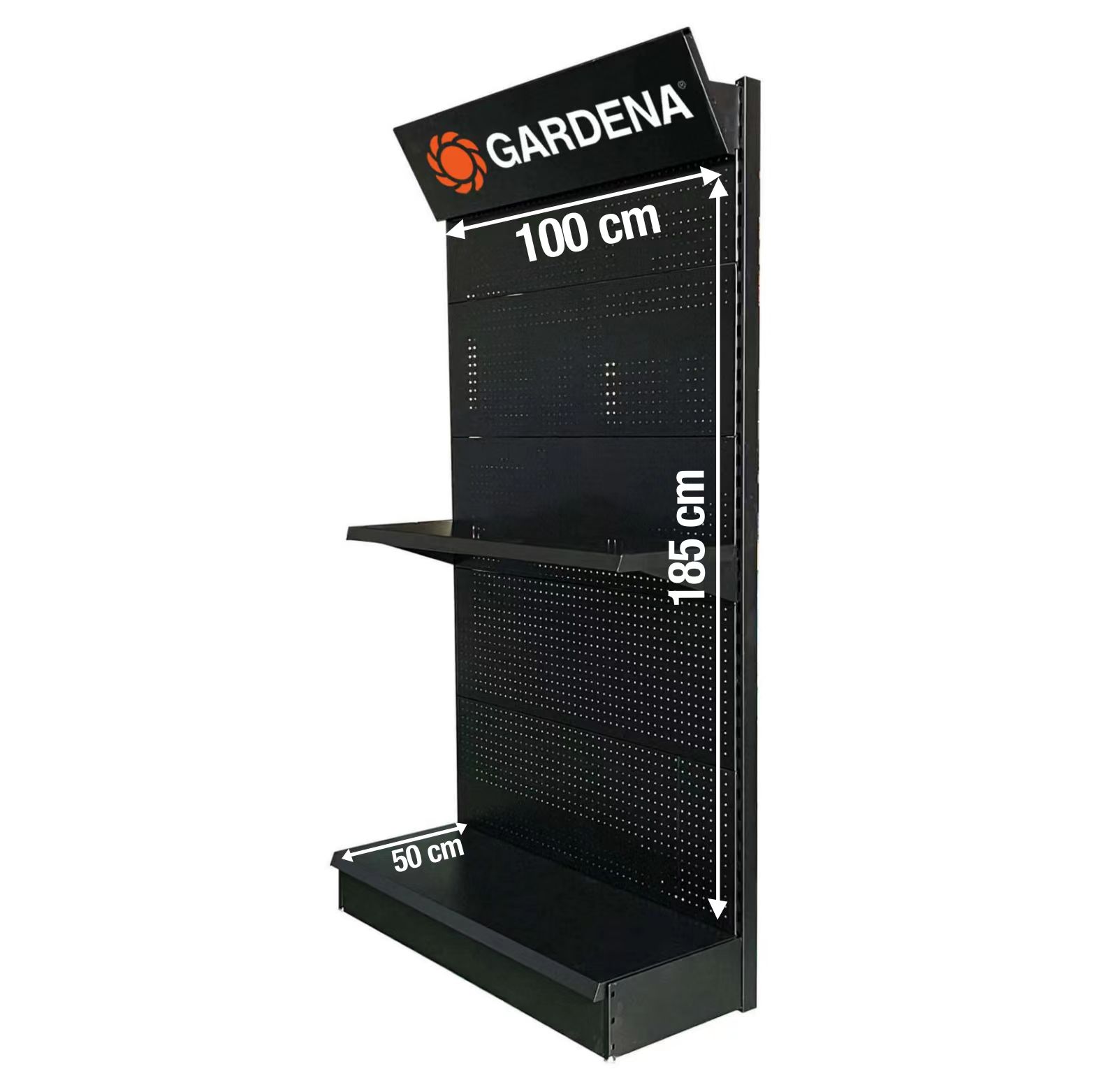

The production process begins with the design phase, where engineers and designers work together to create a blueprint for the hardware display stand. This phase involves considering the specific requirements of the stand, such as its size, weight capacity, and the types of hardware it will be displaying. The design must also take into account any branding or customization requirements from the client.

Material Sourcing and Precision Processing Phase

Once the design is finalized, the production process moves into the material sourcing and preparation phase. High-quality materials, such as steel, aluminum, or plastic, are sourced from trusted suppliers. These materials are then prepared for manufacturing through cutting, shaping, and forming processes. Precision is key during this phase to ensure that the components of the display stand are uniform and meet the required specifications.

Precise Assembly and Structural Reinforcement

Following material preparation, the manufacturing process moves into the assembly phase. This is where the individual components of the hardware display stand are put together. Welding, fastening, and other joining techniques are used to create a sturdy and durable structure. Attention to detail is crucial during assembly to ensure that the stand is not only functional but also visually appealing.

Quality Control Integrated Throughout Production

Quality control is integrated throughout the production process, with inspections and testing conducted at various stages. This ensures that any issues or defects are identified and addressed promptly, preventing costly rework or product recalls down the line.

Final Touches and Branding Application

As the hardware display stand nears completion, the finishing touches are applied. This may include surface treatments such as powder coating, painting, or anodizing to enhance the stand's appearance and provide protection against corrosion or wear. Additionally, any branding elements, such as logos or graphics, are applied during this phase to align with the client's specifications.

Final Inspection and Functional Testing

Once the hardware display stand has been fully assembled and finished, it undergoes a final inspection to verify that it meets all quality standards and specifications. This includes functional testing to ensure that the stand can support the intended hardware and withstand typical usage conditions.

In conclusion, the production process for hardware display stands is a multifaceted endeavor that requires careful planning, skilled labor, and stringent quality control measures. By adhering to best practices and leveraging advanced manufacturing techniques, manufacturers can create display stands that not only showcase hardware effectively but also stand the test of time in various environments.

FAQ: Hardware display rack customization process

Do you want to customize a hardware display stand for your business? Here are some frequently asked questions about the customization process to help you understand the ins and outs of creating a unique display solution for your product.

Q: What is the customization process for hardware display racks?

A: The customization process for hardware display racks involves several steps. First, you need to choose the type of display stand that best suits your product and brand. You can then work with the manufacturer or supplier to discuss your specific customization requirements such as size, color, materials, and any other features you may need.

Q: Can I customize the size and shape of the display stand?

A: Yes, most hardware display rack manufacturers offer the option of customizing the rack size and shape to meet your specific needs. Whether you require a smaller countertop display or a larger floor-standing unit, customization allows you to create a display that perfectly showcases your products.

Q: What materials can be used for customized hardware display racks?

A: Hardware display racks can be customized using a variety of materials, including metal, wood, acrylic, and plastic. The choice of material depends on factors such as the weight of the product, the desired aesthetics, and the overall durability required of the display stand.

Q: How long does the customization process take?

A: The timeline for custom hardware displays may vary depending on the complexity of the customization and the manufacturer's production schedule. It’s important to discuss timelines with your supplier to ensure your custom exhibition stand is ready within the time you require.

Q: Can I add branding and graphics to the display stand?

A: Yes, most hardware display stand customization processes include the option to add branding, logos, and graphics to the stand. This enables you to create a cohesive brand presentation solution that effectively promotes your products.

In summary, the customization process for hardware display racks offers a range of options to create a tailor-made display solution for your business. By understanding the customization process and working closely with a reputable manufacturer or supplier, you can create a display that effectively showcases your products and enhances your brand image.

Post time: May-21-2024