The first step in making an acrylic display stand is the design stage. Skilled designers use computer-aided design (CAD) software to create 3D models of the stands. They take into account the size, shape and function of the stand, as well as any specific requirements or customization options requested by the client. The design phase also involves selecting the appropriate thickness and color of the acrylic sheet to be used.

Once the design is complete, the production process moves into the manufacturing phase. Using precision tools such as laser cutters or saws, the selected acrylic sheet is carefully cut to the desired size and shape. These machines ensure clean and accurate cuts, resulting in high-quality components for display racks.

Next, the cut acrylic parts are carefully sanded and polished to achieve a smooth and aesthetically pleasing finish. This step is crucial as it removes any rough edges or imperfections on the acrylic surface. The polishing process is done using specialized polishing machines and various grades of polishing compounds, gradually refining the surface until the desired clarity and gloss are achieved.

After the grinding process, each part of the acrylic display stand has been carefully assembled. This involves using various techniques such as solvent bonding, which uses solvents to chemically weld acrylic parts together. Solvent bonding creates a strong, seamless seam that is virtually invisible, giving the display a sleek and professional look.

Once assembled, the display stands undergo a thorough quality control inspection. This ensures that each stand meets the required standards for durability, stability and visual appeal. It must be ensured that the display rack can withstand the weight and pressure of the items it is intended to hold while still maintaining the desired shape and appearance.

The final step in the acrylic display stand production process is packaging and shipping. Once the stands have passed quality control inspection, they are carefully packed to protect them during shipping. This usually involves using protective foam or bubble wrap to secure the brace and prevent any damage or scratches. The packed stands are then shipped to their respective destinations for various uses.

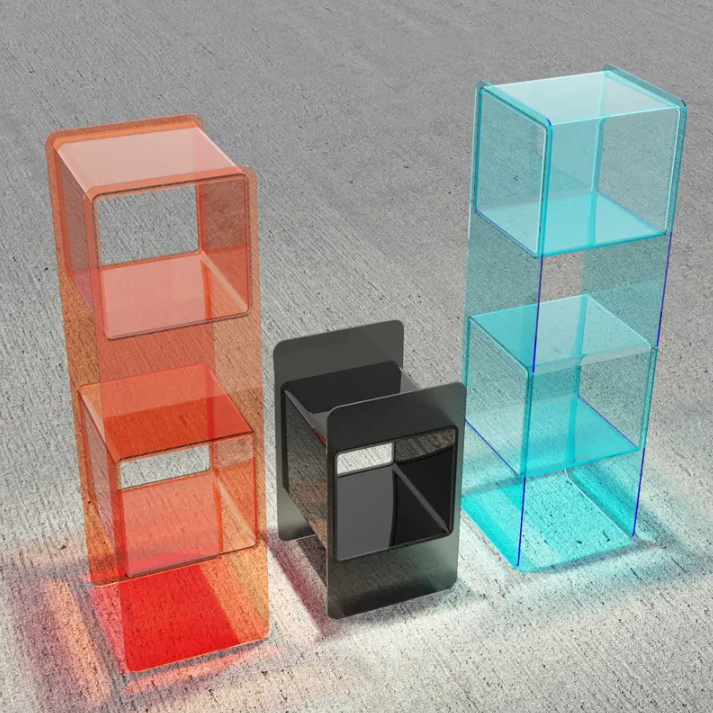

Acrylic display racks have applications in many industries, including retail stores, museums, trade shows and exhibitions. Their versatility allows them to showcase a wide range of products, from jewelry and cosmetics to electronics and art. The transparent nature of acrylic also enhances the visibility of displayed items, making them more attractive and eye-catching.

To sum up, the production process of acrylic display stand involves several stages, including design, fabrication, polishing, assembly, quality control and packaging. Every step is critical to creating a high-quality display that is visually appealing, durable and functional. The use of advanced tools and techniques ensures precision and accuracy throughout the production process and enables the brackets to meet the demanding requirements of various industries. Acrylic display stands remain a popular choice for displaying products due to their versatility, transparency, and overall aesthetic.

Post time: Jun-20-2023